Blog

Unlocking the Power of Best Power Equipment with Comprehensive Technical Specifications and Step by Step Guide

In today's fast-paced world, the demand for reliable and efficient power equipment has skyrocketed, with the global power equipment market projected to reach USD 250 billion by 2025, as reported by reputable industry analysts. This substantial growth underscores the importance of understanding the myriad types of power equipment available and their technical specifications, which are critical in optimizing performance and ensuring safety. By unlocking the potential of these tools—ranging from generators to transformers—users can enhance productivity and operational efficiency in various applications. Our comprehensive guide aims to demystify the complexities of power equipment, providing step-by-step instructions and a detailed look at the benefits that each type brings to the table. Embracing these insights will empower users to make informed decisions, ultimately driving better outcomes in their projects and industries.

Exploring the Top Global Manufacturers of Power Equipment

The world of power equipment has been remarkably transformed by innovations from leading manufacturers. One notable player in this industry is a company specializing in solid oxide fuel cell technology for distributed energy generation. Their server-based systems are known for their exceptional efficiency, reliability, and scalability, making them ideal for both commercial and industrial applications. This technology has the potential to enhance energy security and reduce environmental impact, resonating with the growing global demand for sustainable energy solutions.

Moreover, the electrical equipment market is on an impressive growth trajectory, forecasted to increase significantly over the coming years. This expansion signals a robust appetite for advanced power solutions, driven by technological advancements and rising energy needs across various sectors. The commitment of manufacturers to innovation and quality plays a crucial role in this evolving landscape, as they strive to meet the challenges of a greener future while ensuring economic viability for their products. These trends underscore the importance of comprehensive technical specifications and user-friendly guides in helping consumers navigate the options available in the marketplace.

Detailed Breakdown of Essential Technical Specifications

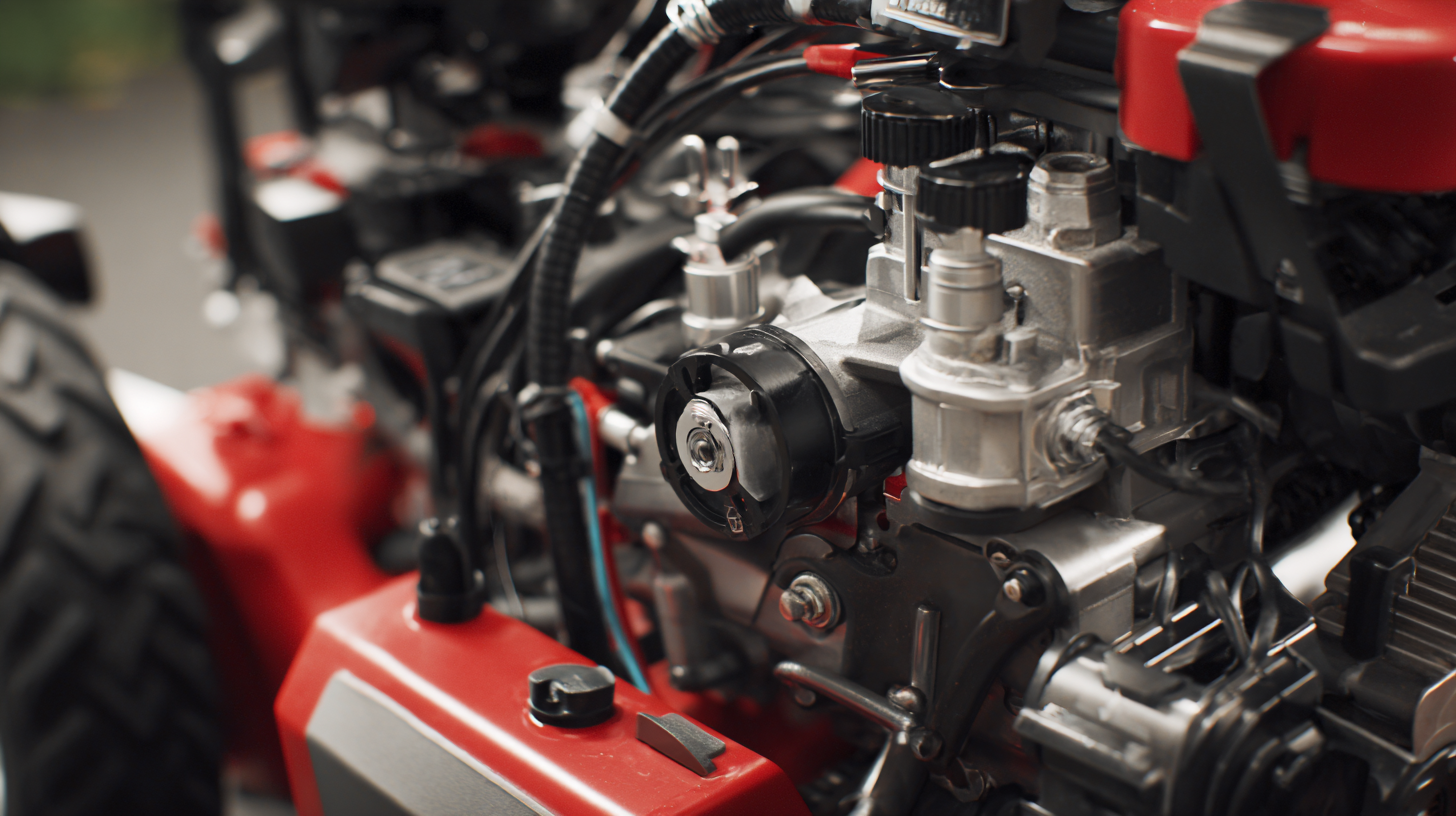

When selecting the best power equipment for your needs, understanding the essential technical specifications is paramount. Factors such as power output, fuel efficiency, and weight play significant roles in determining the effectiveness of your equipment. According to a recent industry report from the Power Equipment Manufacturers Association (PEMA), equipment with higher power-to-weight ratios demonstrates increased efficiency and improved performance in various applications. For example, generators featuring inverter technology often provide cleaner energy output, making them suitable for sensitive electronics and enhancing user experience.

Tip: Always check the manufacturer's data sheets for fuel consumption rates as they can vary significantly. A unit that consumes less fuel can lead to substantial savings in the long run, especially for high-usage scenarios.

Additionally, maintenance specifications are crucial when assessing power equipment. The average lifespan of well-maintained generators can exceed 10,000 hours, but this heavily relies on adherence to manufacturer-recommended servicing schedules. According to industry experts, neglecting routine maintenance can reduce efficiency by up to 30%, highlighting the importance of following a proactive maintenance plan.

Tip: Invest in equipment that comes with comprehensive warranties and customer support. This can save you considerable time and money on repairs and servicing, ensuring consistent equipment performance.

Unlocking the Power of Best Power Equipment

Step-by-Step Guide to Selecting the Right Power Equipment

When selecting the right power equipment for your needs, it's crucial to assess both your project's requirements and the equipment's capabilities. Start by identifying the type of job you'll be tackling—whether it's landscaping, construction, or home renovations. Knowing your specific needs will help narrow down the equipment options available to you.

Tips:

Consider the power source—electric, gas, or battery—as each comes with its own benefits and drawbacks. For instance, electric equipment is often quieter and cleaner, while gas-powered options may provide more power for heavy-duty tasks. It's essential to match the power source with your working environment and frequency of use.

Once you've defined your requirements, research technical specifications such as wattage, fuel efficiency, and the range of features. Reading customer reviews can also provide valuable insights into the equipment’s performance and reliability.

Tips:

Always prioritize safety features, especially for high-powered equipment. Look for features like automatic shut-off, overload protection, and safety guards. Investing in equipment with solid safety protocols can greatly enhance your work experience and minimize risks.

Understanding Industry Standards and Safety Regulations

When it comes to power equipment, adhering to industry standards and safety regulations is paramount. According to a report by the Occupational Safety and Health Administration (OSHA), approximately 7,000 workplace injuries occur each year due to improperly maintained power tools and equipment. Ensuring compliance with ANSI and ISO standards not only helps mitigate these risks but also enhances operational efficiency. For example, the International Organization for Standardization (ISO) lays out specific requirements for equipment durability and safety features, which help manufacturers produce reliable tools that meet user needs.

In addition to national standards, understanding local regulations is critical. The American National Standards Institute (ANSI) outlines various safety protocols that manufacturers must adhere to in order to ensure user safety during equipment operation. A recent survey conducted by the National Institute for Occupational Safety and Health (NIOSH) reported that workplaces that implement these safety standards experience a 40% reduction in accidents related to power equipment. By prioritizing awareness of these regulations and selecting equipment that complies with them, users can not only enhance their safety but also experience increased productivity in their operations.

Maximizing Equipment Performance: Tips for Effective Usage

Maximizing equipment performance starts with understanding the essential technical specifications of power equipment. These specifications can guide users in making informed choices that enhance efficiency and longevity. For instance, the integration of digitization and automation in various industrial processes has shown significant improvements in operational efficiency. This is particularly evident in sectors like lithium production, where variable brine conditions necessitate precise management. By leveraging data analytics, operators can enhance decision-making and maintenance strategies, which contributes to more effective equipment usage.

Furthermore, embracing advanced technologies such as AI and big data can transform the way equipment is monitored and utilized. In manufacturing, this means adopting systems that not only track performance metrics in real-time but also predict potential issues before they escalate into costly failures. Companies looking to optimize their operations should focus on implementing a holistic approach, encompassing not just the procurement of high-quality equipment, but also the adoption of innovative practices that promote sustainability and efficiency. By doing so, they can not only meet production goals but also contribute to wider energy optimization efforts in their industries.