Blog

What is Construction Equipment Parts and How to Choose the Right Ones

In the construction industry, the efficiency and reliability of machinery heavily depend on the quality of construction equipment parts. These essential components play a critical role in maintaining the performance and longevity of heavy machinery used at job sites. Understanding what construction equipment parts encompass and how to choose the right ones can significantly enhance operational efficiency and reduce downtime.

Selecting the appropriate parts is not merely about finding replacements; it requires a deep understanding of the specific needs of each machine and the conditions in which they operate. Whether you're dealing with excavators, bulldozers, or other heavy machinery, knowing how to identify and source the correct parts ensures optimal functioning and safety on-site. In this guide, we will explore various types of construction equipment parts, their significance in construction projects, and key considerations to keep in mind when making purchasing decisions. With the right knowledge, construction professionals can ensure that their equipment remains in top condition, ultimately leading to successful project outcomes.

Understanding Construction Equipment Parts

Understanding construction equipment parts is essential for ensuring the efficient operation and longevity of various machinery used on job sites. These parts encompass a wide range of components, including engines, hydraulics, attachments, and undercarriages, each playing a critical role in the functionality of the equipment. Familiarizing oneself with these components helps operators and managers recognize signs of wear and tear and understand when maintenance is necessary, thereby preventing costly breakdowns and downtime.

When selecting the right construction equipment parts, several factors should be considered. First, compatibility with the specific machinery is crucial; using parts that are designed to fit seamlessly into the equipment ensures optimal performance. Additionally, evaluating the quality of materials used in the parts can significantly affect their durability and efficiency. It's also beneficial to consider the availability of replacement parts and the support services offered by suppliers, which can ease future repairs and maintenance challenges. By taking these factors into account, one can make informed decisions that enhance the effectiveness and reliability of construction equipment.

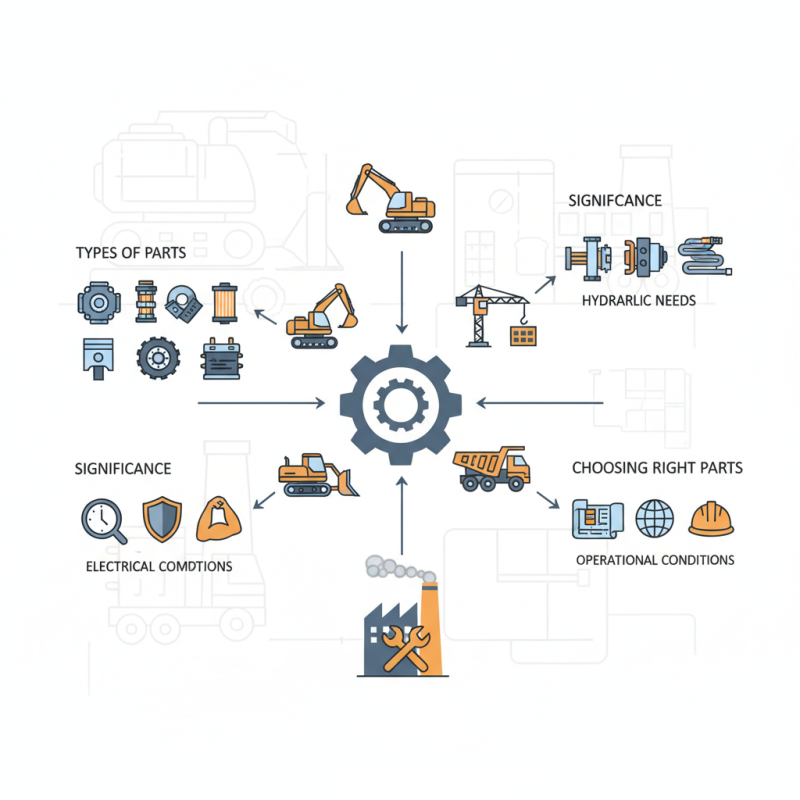

Categories of Construction Equipment Parts

When it comes to construction equipment, understanding the various categories of parts is essential for maintaining optimal performance and ensuring safety. Construction equipment parts can be broadly classified into several categories, each serving unique functions. Major categories include engine components, hydraulic parts, electrical systems, and body components. Engine components encompass items such as filters, gaskets, and belts, which are crucial for smooth engine operation. Hydraulic parts, including pumps, cylinders, and hoses, play a critical role in enabling movement and ensuring the efficiency of machinery.

Another vital category is electrical systems, which consist of wiring, batteries, and sensors that govern the functionality of the equipment. Proper maintenance and timely replacement of these parts are integral to preventing operational failures. Lastly, body components, such as frames, panels, and tracks, are essential for the structural integrity of the equipment. When selecting construction equipment parts, it's important to consider compatibility, durability, and the specific requirements of the job at hand. This ensures the equipment can withstand demanding conditions while delivering reliable performance on the construction site.

What is Construction Equipment Parts and How to Choose the Right Ones - Categories of Construction Equipment Parts

| Category | Part Type | Description | Choosing Tips |

|---|---|---|---|

| Excavators | Bucket | Used for digging and moving material. | Consider size and shape based on project requirements. |

| Bulldozers | Blade | Used for pushing large quantities of soil and debris. | Ensure compatibility with the machine model. |

| Crushers | Jaw Plate | Crushes and grinds material for recycling. | Select material grade for durability and performance. |

| Loaders | Bucket | Used for loading materials onto trucks. | Assess load capacity and attachment options. |

| Forklifts | Forks | Used for lifting and moving materials on pallets. | Choose correct lift height and weight capacity. |

Factors to Consider When Choosing Construction Parts

When selecting construction equipment parts, several critical factors must be taken into consideration to ensure optimal performance and longevity of machinery. Firstly, compatibility with existing equipment is paramount. According to a recent report by the Association of Equipment Manufacturers, about 30% of equipment failures are attributed to the use of incompatible parts. Before making a purchase, it is essential to verify the specifications of the equipment and match them with the parts to avoid costly downtimes and repairs.

Another important aspect to consider is the quality of the parts. A study by the Machinery of America Association highlights that using genuine or OEM parts can result in a 25% increase in the efficiency of machinery compared to aftermarket alternatives. Investing in high-quality parts not only enhances the overall performance of construction equipment but also contributes to safety on the job site, where equipment reliability is crucial. Additionally, factors such as warranty coverage, availability of support, and supplier reputation should also play a role in the decision-making process, ensuring that construction businesses can maintain their operations smoothly and efficiently.

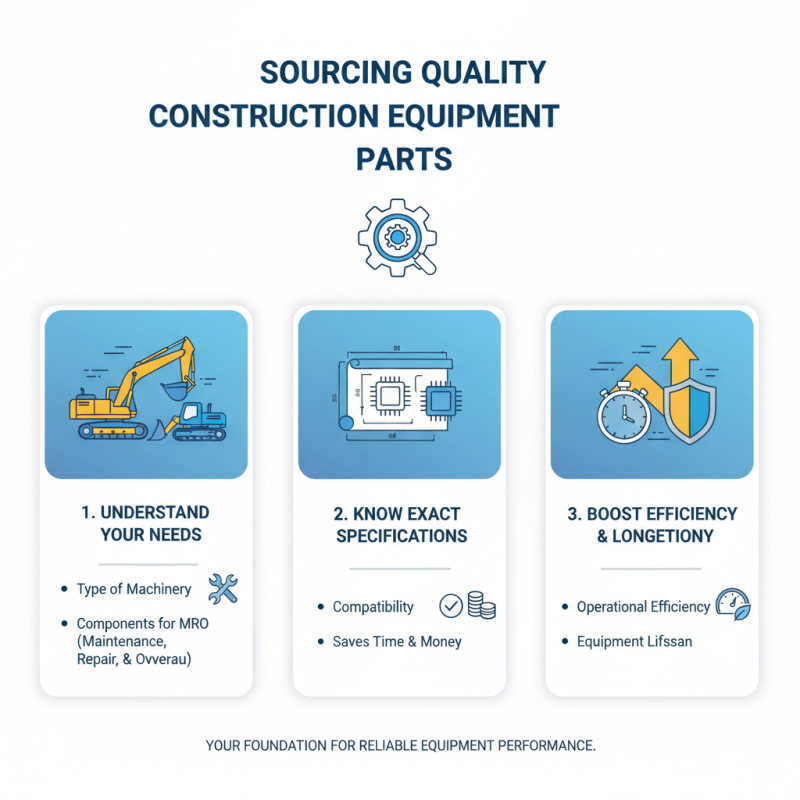

How to Source Quality Construction Equipment Parts

When sourcing quality construction equipment parts, it’s crucial to start with a thorough understanding of your specific needs. Consider the type of machinery you use and the components that require maintenance or replacement. Knowing the exact specifications can save time and money, as it ensures you only invest in parts that are compatible with your equipment. This foundational step not only boosts operational efficiency but also enhances the longevity of your machinery.

Tips: Always consult your equipment’s manual for detailed part numbers and descriptions before purchasing. This will give you clarity and help avoid costly errors. Additionally, consider reaching out to experienced professionals for recommendations on reliable suppliers.

Another important aspect is assessing the quality of the parts. Look for suppliers that provide warranties or guarantees, as this reflects their confidence in the product. It's also beneficial to read customer reviews and case studies to gauge supplier reliability. Engaging with a community of construction professionals can provide insights into reputable vendors and common pitfalls to avoid.

Tips: Keep track of important measurements and specifications while shopping, as this will simplify the process of evaluating different options. Be diligent about cross-checking parts against your original equipment to ensure compatibility.

Maintenance Tips for Construction Equipment Parts

Maintaining construction equipment is essential for maximizing efficiency and minimizing downtime. Regular maintenance of equipment parts can lead to significant cost savings, as documented in various industry reports, which highlight that proper maintenance can reduce repair costs by up to 50%. It is crucial to establish a routine maintenance schedule, including inspections of critical components such as engines, hydraulics, and electrical systems, to identify potential issues before they escalate.

Tips for maintenance include keeping a detailed log of all repairs and replacements performed on the equipment. This log helps in tracking the performance of various parts and assessing their lifespan. Additionally, always refer to the manufacturer's specifications for suggested maintenance intervals and part replacements. Regularly cleaning equipment parts, especially filters and cooling systems, can prevent blockages that lead to overheating and increased wear.

Furthermore, investing in quality parts can significantly impact the longevity of your equipment. Opt for parts that meet industry standards, as subpar components can compromise the integrity of the entire system. According to industry experts, using genuine replacement parts can enhance the performance and reliability of construction equipment, leading to improved operational efficiency and cost-effectiveness. Always stay informed about the latest maintenance practices and technological advancements to ensure your equipment remains in peak condition.

Maintenance Frequency of Construction Equipment Parts

This bar chart illustrates the maintenance frequency of various construction equipment parts throughout the year. Regular maintenance is crucial for ensuring the longevity and efficiency of the equipment. As observed, filters require the highest maintenance frequency, followed closely by tracks and hydraulic parts.

Related Posts

-

Benefits of Using High Quality Construction Equipment Parts for Enhanced Performance

-

Essential Tips for Choosing the Right Construction Equipment Parts for Optimal Performance

-

What Types of Construction Equipment Parts Are Essential for Your Projects

-

7 Effective Tips for Sourcing Quality Construction Equipment Parts to Boost Your Operations

-

7 Compelling Reasons Why "Best Construction Machinery" Revolutionizes Your Global Procurement Strategy

-

Leading Global Exporter of Top-Tier Heavy Construction Equipment: A Factory's Success Story