Blog

2025 Top Excavator Parts Guide for Optimal Performance and Durability

When it comes to maintaining and maximizing the performance of heavy machinery, the importance of high-quality excavator parts cannot be overstated. As excavators continue to play a critical role in construction, mining, and various excavation projects, understanding the components that contribute to their optimal performance and durability is essential for operators and fleet managers alike. This guide aims to provide insightful information about the key excavator parts that are vital for ensuring the longevity and efficiency of these machines.

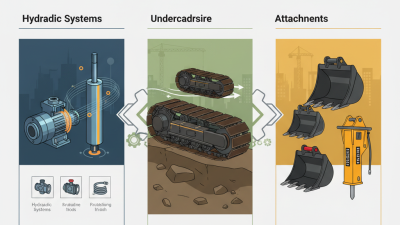

In the fast-paced world of heavy equipment, neglecting the quality and suitability of excavator parts can lead to increased downtime and maintenance costs. Key components, such as hydraulic systems, undercarriages, and attachment tools, each play a unique role in the overall performance of excavators. By selecting the right parts and focusing on their routine maintenance, operators can prevent operational failures and enhance productivity on the job site. This guide will delve into the latest advancements and essential features of excavator parts, equipping readers with the knowledge to make informed decisions that bolster their machinery's performance and durability for the years to come.

Essential Excavator Parts for Enhanced Performance in 2025

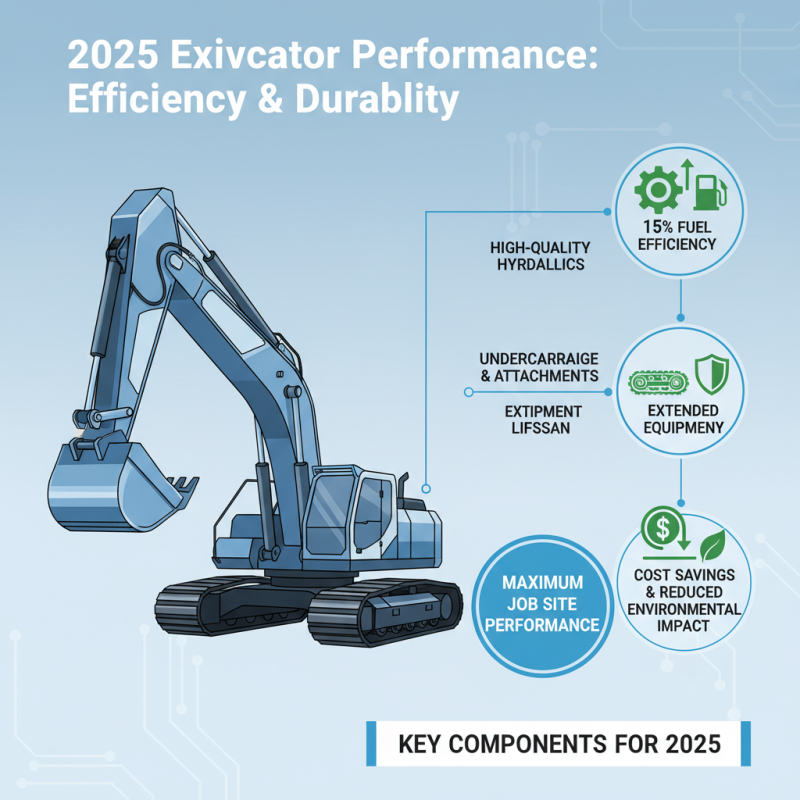

In 2025, the efficiency and durability of excavator parts will be pivotal for operators seeking to maximize performance on job sites. Essential components such as hydraulic pumps, undercarriages, and attachment systems are crucial for not only enhancing productivity but also extending equipment lifespan. According to industry reports, maintaining high-quality hydraulics can significantly improve fuel efficiency by up to 15%, which translates directly to cost savings and reduced environmental impact.

Tips: Regularly inspecting and replacing worn hydraulic filters can prevent costly repairs and downtime. Operators are advised to establish a routine maintenance schedule to ensure vital components are always in optimal condition.

Moreover, the role of innovative materials in manufacturing excavator parts cannot be overlooked. The shift towards lightweight, high-strength alloys and advanced composites is creating parts that resist wear and corrosion better than ever before. A recent analysis highlighted that excavators fitted with updated undercarriage designs showed an increased operational life by approximately 20%, underscoring the importance of investing in quality parts for long-term benefits.

Tips: Consider investing in parts designed with advanced wear-resistant materials, which provide improved longevity and reduce the frequency of replacements. Making informed choices about part materials can greatly enhance the overall performance of your excavators in the long run.

Key Factors Influencing Excavator Part Durability

When evaluating the durability of excavator parts, several key factors come into play. The quality of materials used in manufacturing components is crucial. High-grade steels and advanced composites often resist wear and tear better than standard materials. Furthermore, enhancements such as heat treatment or alloying techniques can significantly improve the hardness and strength of parts, thereby extending their lifespan even under strenuous operational conditions.

Another vital aspect influencing durability is the design and engineering of the parts themselves. Components that are designed with efficient stress distribution in mind tend to perform better, as they minimize the risk of fractures and failures. Factors such as thickness, shape, and the inclusion of reinforcements in critical areas can make a substantial difference. Regular maintenance routines and proper operating practices also play a pivotal role, as they can prevent premature wear, ensuring that excavator parts retain their integrity and functionality for a more extended period.

2025 Top Excavator Parts Durability Analysis

Comparative Analysis of Aftermarket vs. OEM Excavator Parts

When considering excavator parts, the choice between aftermarket and OEM (Original Equipment Manufacturer) components is crucial for ensuring optimal performance and durability. A comparative analysis reveals that while OEM parts are engineered to meet specific manufacturer standards, aftermarket parts can often provide cost-effective solutions without sacrificing quality. According to a recent industry report by the Equipment Manufacturers Association, up to 30% of contractors reported that choosing aftermarket parts led to equal or improved performance in their excavators, particularly for non-critical components.

However, it’s essential to approach aftermarket options with caution. While many aftermarket providers compete directly with OEMs on quality, their adherence to manufacturing standards can vary significantly. Research from the Construction Equipment Research Institute notes that about 20% of aftermarket parts fail to meet the required specifications, which can lead to increased maintenance costs or even safety risks in the long run.

**Tips:**

1. Always verify the certifications of aftermarket parts to ensure they meet industry standards.

2. Consider the long-term performance and not just the upfront cost; a slightly higher investment in reliable parts can save money on repairs over time.

3. Consult with industry professionals or refer to performance reviews to gauge the reputation of aftermarket suppliers before making a decision.

2025 Top Excavator Parts Guide for Optimal Performance and Durability

| Part Type | OEM Parts Performance | Aftermarket Parts Performance | Cost Comparison | Warranty Period |

|---|---|---|---|---|

| Hydraulic Cylinder | Excellent | Good | $1,500 (OEM) vs $1,200 (Aftermarket) | 12 months |

| Final Drive | Very Good | Good | $3,000 (OEM) vs $2,200 (Aftermarket) | 18 months |

| Bucket | Excellent | Fair | $2,000 (OEM) vs $1,500 (Aftermarket) | 24 months |

| Track Roller | Good | Very Good | $600 (OEM) vs $450 (Aftermarket) | 12 months |

| Sprocket | Fair | Good | $700 (OEM) vs $500 (Aftermarket) | 12 months |

Maintenance Tips for Prolonging Excavator Part Lifespan

Proper maintenance is essential for prolonging the lifespan of excavator parts and ensuring optimal performance. Regular inspections should be part of a scheduled maintenance plan, focusing on critical components such as hydraulic systems, tracks, and buckets. Operators should check for wear and tear, as well as any signs of fluid leaks, which can indicate deeper issues. Keeping the machine clean not only improves its efficiency but also helps in identifying potential problems early on. Simple practices such as cleaning debris off tracks and ensuring that hydraulic lines are free from obstructions can make a significant difference.

Lubrication is another vital aspect of maintaining excavator parts. Properly lubricated components reduce friction and wear, thus extending their life. Operators should adhere to the manufacturer's guidelines regarding lubrication intervals and quantities for each part. Additionally, using high-quality lubricants tailored for the specific environment in which the excavator operates can enhance protection against corrosion and overheating. Implementing a proactive approach to maintenance not only aids in durability but also maximizes productivity, minimizing downtime and repair costs in the long run.

Innovative Technologies in Excavator Parts for 2025

The excavation industry is undergoing a significant transformation in 2025, driven by innovative technologies aimed at enhancing performance and durability. Advanced materials such as high-strength, lightweight alloys and composites are now being utilized in the production of key excavator components. These materials not only improve the structural integrity of parts but also reduce the overall weight of the machinery, facilitating better fuel efficiency and operational effectiveness. According to a recent industry report, the use of lightweight materials is expected to enhance fuel efficiency by up to 15%, providing significant cost savings over the machinery's operational lifespan.

Moreover, the integration of automation and smart technologies into excavator components is revolutionizing operational capabilities. The rise of Internet of Things (IoT) technology allows for real-time monitoring and data collection on machine performance, enabling predictive maintenance and minimizing downtime. A study by equipment manufacturers indicates that implementing these technologies can reduce maintenance costs by approximately 20%, while simultaneously extending the lifespan of critical components. This focus on smart excavator parts is leading to a more proactive approach to equipment management, ensuring optimal performance and durability in the demanding environments where excavators operate.

Related Posts

-

Top Excavator Parts to Consider in 2025: Essential Buying Guide

-

Future Trends in Best Excavator Parts Market Analysis for 2025 with Real World Examples

-

What Types of Construction Equipment Parts Are Essential for Your Projects

-

Benefits of Using High Quality Construction Equipment Parts for Enhanced Performance

-

The Ultimate Guide to Choosing the Right Excavator Parts for Maximum Efficiency and Performance

-

Essential Tips for Choosing the Right Construction Equipment Parts for Optimal Performance